Introduction to Oracal Vinyl

Feb 13th 2024

Introduction

Oracal is one of the leading high-quality vinyl films for sign-making, vehicle graphics, pinstriping, and general decor. The Germany-based company Orafol has been producing premium vinyl since 1965, offering a range of products unrivaled in longevity, ease of application, and cutting-edge technology.

Popular Calendered and Cast Vinyl from Oracal:

- Oracal 651 - The flagship economy-grade vinyl for basic lettering and graphics.

- Oracal 751 – Value-priced 8-year cast film for durable, dimensionally stable applications.

- Oracal 951 - High-performance cast vinyl film for challenging applications.

With consistent quality and technology innovations, Oracal has become an essential brand for sign-makers, graphics installers, and vehicle wrappers. Their vinyl films deliver premium durability and ease of use that professionals trust for high-impact projects. For do-it-yourself crafters, Oracal provides user-friendly options to customize a range of surfaces affordably.

Understanding Oracal 651 Vinyl

Oracal 651 vinyl is considered an industry vinyl that is easy to work with and budget-friendly. Here are some of its key features and benefits:

Features

- Thickness of 2.5 mils - perfect for indoor and short-term outdoor projects

- Permanent adhesive for most common application surfaces

- Gloss finish provides vibrant colors

- Good cutting and weeding properties

Benefits

- Cost-effective option

- Wide range of solid colors and finishes available

- Can be used on curved and corrugated surfaces

- Decent durability for short-term use

Oracal 651 is well-suited for:

- Multitudes of indoor and outdoor applications

- Craft projects like tumblers and laptop skins.

- Outdoor signage

- Displays in retail stores and trade show booths.

Oracal 651 has a permanent adhesive that adheres well to:

- Flat, smooth surfaces like glass and plastic

- Painted drywall and wood

- Polycarbonate, acrylic, and ABS sheets

- Ceramics, tile, and sealed concrete

It may have reduced adhesion on textured or porous surfaces, so surface preparation is recommended. Overall, Oracal 651 is a versatile beginner vinyl for basic crafting and temporary signage needs.

Comparing Oracal 651 and 751

Oracal 651 and 751 are both popular options in the Oracal vinyl series, but they have some key differences durability, adhesives, and ideal usage.

Durability Comparison

Oracal 751 is the more durable vinyl between the two. Formulated to withstand up to 8 years outdoors without fading, cracking or peeling when properly cared for. Oracal 651 on the other hand is rated for up to 4 years outdoors.

For indoor use, Oracal 751 can last up to 10 years if applied to

a smooth, flat surface. Oracal 651 has an indoor durability of around 6 years. So for projects that need a long-lasting vinyl that can handle outdoor elements, Oracal 751 is the preferable choice.

Adhesive Quality

Oracal 751 uses an acrylic-based adhesive that forms a better bond on a wider variety of surfaces including textured or curved applications. The adhesive is also more resistant to extreme heat and humidity changes.

Oracal 651 uses a solvent-based adhesive. While cheaper, it may not adhere as well to irregular surfaces. It also becomes less effective in high heat, such as on vehicle hoods.

Ideal Applications

Oracal 651 is best suited for short-term indoor signage, decals, and craft projects where durability is not as critical. Its lower cost makes it ideal for prototypes or temporary applications.

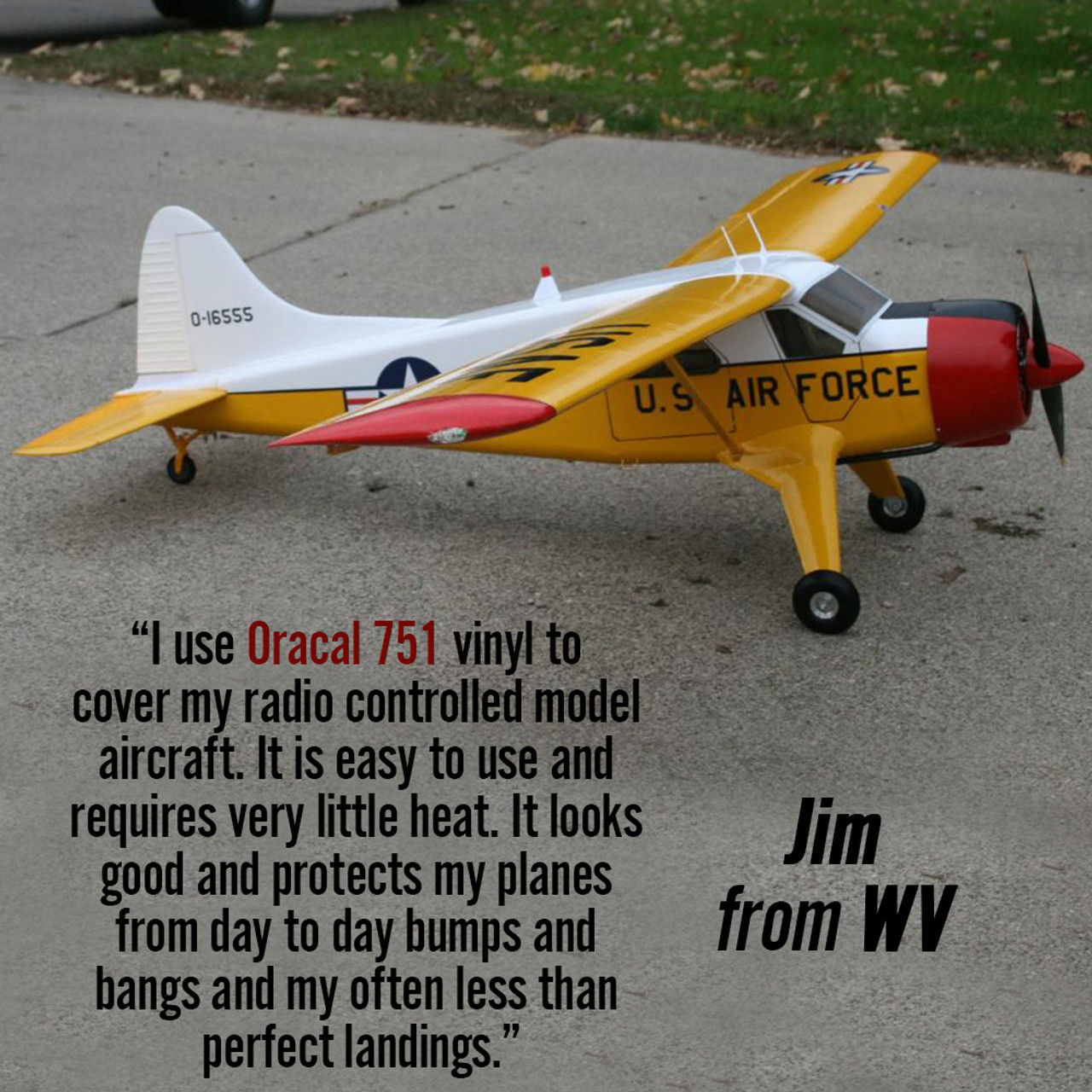

Oracal 751's durability lends itself better to long-term outdoor signage, vehicle graphics, and applications where resistance to weathering is important. The enhanced adhesive also makes it suitable for textured or curved surfaces like brick walls, tumblers and computer cases.

So for more permanent vinyl applications, Oracal 751 is worth the additional cost. But for temporary indoor use, Oracal 651 provides good value.

Deep Dive into Oracal 751

Oracal 751 vinyl offers exceptional durability, making it one of the most popular choices for outdoor and vehicle applications. Here's an in-depth look at what makes Oracal 751 stand out:

Benefits and Advantages

Oracal 751 is designed to withstand exposure to harsh weather conditions. The vinyl film is thicker than lower-grade options at 3.5 mil, providing extra resistance against UV rays, moisture, and temperature fluctuations. 751 features an acrylic adhesive that creates a tenacious bond to surfaces. This adhesive contains UV inhibitors that prevent it from deteriorating over time outdoors.

751 also has a smooth, glossy finish that helps shed dirt and debris. This is particularly useful for vehicle graphics, as it stays cleaner looking than textured vinyl. The vinyl's conformability allows it to adhere smoothly over curves, rivets, and corrugations. Oracal 751 has an expected outdoor lifespan of 7 years for vehicle graphics and 10 years for signage when properly cared for.

Outdoor Durability

Oracal guarantees 751 will intact and legible for 7 years on vehicles and 10 years on flat surfaces with vertical exposure. Real-world performance often exceeds these timeframes. The key factors that make 751 so durable outdoors are:

- Thick 3.5 mil vinyl resists tears, shrinkage, and damage from impacts.

- Non-PVC film material stays flexible and won't crack or peel.

- Gloss finish sheds dirt, moisture, and contaminants.

- Acrylic adhesive bonds securely and contains UV blockers.

751 maintains a high level of performance through extreme temperature shifts, humidity, salt air exposure, and other environmental factors. Proper application and maintenance will maximize longevity.

Application Tips

To get the most out of Oracal 751 for your projects, follow these application tips:

- Ensure the surface is clean and dry before applying vinyl. Smooth, non-porous surfaces like glass, metal or paint work best.

- Use an alcohol wipe or primer if needed for low surface energy substrates.

- Always heat the material before stretching over complex curves and corrugations.

- For vehicle wraps, use the dry application method and use a heat gun to form the vinyl around details.

- Cut lettering and designs from 751 using a sharp blade or vinyl cutter. Weed carefully.

- Apply transfer tape then rub firmly to secure the vinyl graphics during transfer.

- Smooth out air pockets and bubbles using a squeegee for best adhesion.

With proper application and care, Oracal 751 vinyl delivers reliable, durable graphics and signs that maintain their attractive appearance over time.

Oracal 951: The Premium Vinyl

Oracal 951 vinyl is considered the premium choice within the Oracal series for several key reasons:

Unique Features and Benefits

Oracal 951 stands out for its unrivaled durability and longevity. With a thickness of 4.5 mil, it is 50% thicker than Oracal 651 and 20% thicker than Oracal 751. The increased thickness provides excellent protection against abrasion, fading, and typical wear and tear.

In addition, Oracal 951 utilizes a transparent, glossy polymeric PVC film specially engineered to resist UV radiation, scratches, and humidity. This gives it superior weathering properties compared to other vinyl in the series.

Oracal 951 also features an ultra-strong solvent-based acrylic adhesive that creates an incredibly durable bond. This adhesive adheres well even on challenging surfaces like low-energy plastics.

Longevity

With proper care and application, Oracal 951 vinyl graphics and lettering can last upwards of 10 years outdoors. The combination of protective laminates and UV-resistant inks prevents fading, cracking, and peeling over time.

Indoors, Oracal 951 can remain flawless for decades if applied to smooth, clean surfaces. It resists yellowing, denting, and other age-related issues better than lower-grade vinyl.

Versatility

Oracal 951 works beautifully on a diverse array of surfaces including metals, high/low-energy plastics, glass, sealed wood, and more. The strong solvent adhesive ensures excellent adhesion on uneven and textured surfaces as well.

This vinyl can be used for vehicle wraps, architectural signage, outdoor advertising, POS displays, and any application needing maximum durability. It also cuts well on plotter machines and weeds easily for detailed decals and graphics.

Installation Techniques

Proper surface prep is crucial when installing Oracal 951 for long-lasting results. Ensure the substrate is clean, dry, and free of grease, wax, or paint. Lightly scuffing glossy surfaces can improve adhesion.

Slowly remove the liner at a low angle while applying the graphic. Use a plastic applicator to smooth it out, working from the center outward. Apply ample pressure, especially on edges, rivets, and corrugations.

After application, allow 2-3 days for the adhesive to fully cure before washing. Avoid harsh cleaners, pressure washing, or abrasives. Use heat to improve conformability around complex contours.

With its unmatched durability and application versatility, Oracal 951 is the clear choice for demanding outdoor signage or fleet wrap projects where maximum performance is required.

Technical Specifications of Oracal Vinyl Series

Oracal vinyl comes in a range of thicknesses and finishes to suit different applications.

Thickness

- Oracal 651 has a thickness of 2.5mil, making it a lightweight and economical choice.

- Oracal 751 is slightly thicker at 3.5mil for increased durability and longevity.

- Oracal 951 is the thickest option at 5.5mil, providing maximum protection for long-term outdoor use.

Adhesives

- Oracal 651 features a pressure-sensitive solvent acrylic adhesive.

- Oracal 751 has a permanent pressure-sensitive solvent acrylic adhesive.

- Oracal 951 uses an extra-strength permanent pressure-sensitive acrylic adhesive.

Finishes

- Oracal 651 comes in glossy and matte finishes.

- Oracal 751 is available in gloss, matte, transparent, and specialty finishes like glitter, reflective, and mirrored options.

- Oracal 951 comes in gloss, matte, and transparent finishes. The thicker 951 material allows for crisp detail on specialty finishes.

In summary, Oracal vinyl series offers a range of thicknesses, adhesive strengths, and finish types to suit indoor or outdoor applications, short- or long-term use, and different design needs.

Application Techniques

Proper application is key to getting the most out of Oracal vinyl and ensuring it adheres smoothly and cleanly. Follow these application tips:

Surface Preparation

- Clean the surface thoroughly with isopropyl alcohol to remove any dirt, dust, oil or grease. This helps the vinyl stick properly.

- For outdoor applications, wipe down the surface with a degreaser or ammonia-based cleaner. Rinse off any residue.

- Use a razor blade to scrape off any existing paint or decor that is flaking or peeling.

- Sand uneven surfaces to create a smooth foundation.

- Allow freshly painted surfaces about 2 weeks to fully cure before applying vinyl.

Transfer Methods

- For small decals, remove the backing and press the vinyl onto the surface using a squeegee or credit card to smooth it out. Remove the transfer tape carefully.

- For larger decals, tape one edge of the vinyl to the target surface. Peel back the backing as you use a squeegee to adhere the vinyl smoothly.

- For vehicle wraps, use the "dry method" - don't use application fluid. Pull the backing off as you tack sections at a time, heating the vinyl with a heat gun while smoothing out air pockets.

- For wall murals, lightly spray the back of the vinyl with application fluid. Use felt squeegees in overlapping strokes to transfer the image.

Removal Tips

- Heat the vinyl with a blow dryer or heat gun to soften the adhesive and make removal easier.

- Peel off slowly at a sharp angle to avoid damaging the underlying surface.

- Use a plastic scraper to lift any sticky residue. Finish cleaning with isopropyl alcohol.

- For vehicle wraps, use wrap release solution and pull the vinyl off in sections while spraying.

Outdoor Versus Indoor Use

When comparing indoor vs outdoor vinyl, Outdoor vinyl projects require special consideration compared to indoor applications. When used outside, vinyl will be exposed to elements like sunlight, moisture, temperature fluctuations, and pollutants which can impact its durability and longevity.

Durability and Lifespan

Oracal vinyl’s are designed for extended outdoor use. With proper application and care, Oracal 651 has an expected durability of 5 years outdoors, while Oracal 751 is warranted for 7 years and Oracal 951 for 10 years.

For indoor use, Oracal vinyl’s will typically last much longer without signs of wear or fading. Indoor vinyl may last 10+ years if applied to smooth, clean surfaces.

Vinyl used outdoors will need more frequent inspection, maintenance, and occasional replacement compared to indoor vinyl. Factors like mechanical wear from wind, rain, and debris can degrade outdoor vinyl over time.

Maintenance Needs

Outdoor vinyl requires vigilant cleaning to prevent buildup of dirt, pollutants, mold, and mildew. A periodic pressure wash or scrub with mild soap and water is recommended every 6 months.

For indoor vinyl, occasional dusting or wiping with a damp cloth is sufficient maintenance in most cases. Only non-abrasive cleaners should be used indoors.

Recommendations by Project

For short-term outdoor signage or graphics needed for events, promotions or seasonal displays, Oracal 651 provides good durability at a moderate price point.

For long-term outdoor applications like business signs, vehicle graphics or architectural signage, premium Oracal 951 will provide maximum longevity and weather resistance.

For any permanent indoor vinyl applications, Oracal 651 offers an ideal balance of quality, ease of use and affordability. Choose gloss or matte finishes based on the desired aesthetic.

Consider ease of installation and removal when choosing vinyl for temporary indoor signage or decor. Oracal 651's removable adhesive is a smart option for short-term indoor projects.

Cutting and Weeding Tips

Proper cutting techniques and weeding are crucial steps for a clean, professional vinyl application. Follow these tips when working with Oracal vinyl cutting settings:

Cutting Machine Settings

- Set the blade depth between 50-70% of the material thickness for clean cuts. Test on a scrap piece first.

- Adjust the blade offset so the blade is cutting directly on the vinyl's edge, not inside or outside the defined cut lines.

- For small text and detailed cuts, slow down the cutting speed and perform 2-3 test cuts to check cut quality before sending the final job.

- Set the cutting pressure high enough to cleanly cut through the vinyl but not so high that it cuts into the backing paper.

Weeding Techniques

- Weed soon after cutting while the vinyl is still warm and pliable from the cutting process. This prevents the adhesive from fully setting.

- Use a weeding tool with a sharp, angled tip to grab onto the waste material and lift it away. Avoid using dull tools that could scratch the vinyl.

- For small, intricate weeding, use tweezers to grab and remove the excess material.

- Weed at a 45° angle to the backing material. Avoid pulling straight up as this can lift sections of vinyl you want to keep.

- Work methodically from one section to the next. Don't try to weed the entire design all at once.

- For layered vinyl projects, weed from the top layer down.

Troubleshooting Tips

- If the vinyl tears during weeding, gently re-press it down before continuing to avoid further tearing.

- To remove excess adhesive left behind, use adhesive remover or rubbing alcohol. Test on a scrap piece first.

- If the blade doesn't fully cut through the material, the machine settings need adjusting. Increase the blade depth or cutting pressure.

- For small vinyl pieces that lift during weeding, apply transfer tape before weeding to secure them.

Proper machine setup, following the right techniques, and troubleshooting any issues ensures a smooth weeding process for Oracal vinyl projects. Test different settings and methods to find what works best for each vinyl type.

Creative Uses

Oracal vinyl opens a world of creative possibilities for DIYers and professionals alike. Here are some inspiring ways to use Oracal vinyl for custom projects:

Signage

Oracal vinyl is ideal for creating custom signs and lettering for homes, businesses, events, and more. All three vinyl options can be used, depending on your specific needs. For indoor signs that won't be exposed to lots of wear, Oracal 651 is a great option. For outdoor durability, choose Oracal 751 or 951.

Play with different colors, finishes, and application techniques to make signs that are exactly what you envisioned.

Vehicle Wraps

Transform your car, boat, ATV, or other vehicle into a moving work of art with a full or partial vinyl wrap using Oracal films. Complex wraps require the services of a professional installation expert, while beginners can start with easier targeted wraps, like a racing stripe or logo on the hood. Use high performance Oracal 951 for vehicle wraps to get automotive-grade durability.

Home Decor

Add stylish accents to any room with vinyl decals and wall art using Oracal films. Create monograms, inspirational quotes, geometric shapes, wall murals, window decor, and more. Use glossy finish vinyl’s for a slick modern look or matte for an elegant subtle texture. Switch up your decor over time by simply peeling off and replacing decals.

The possibilities are endless with Oracal vinyl! It provides the perfect medium for crafters and creatives to make their imaginative ideas a reality.